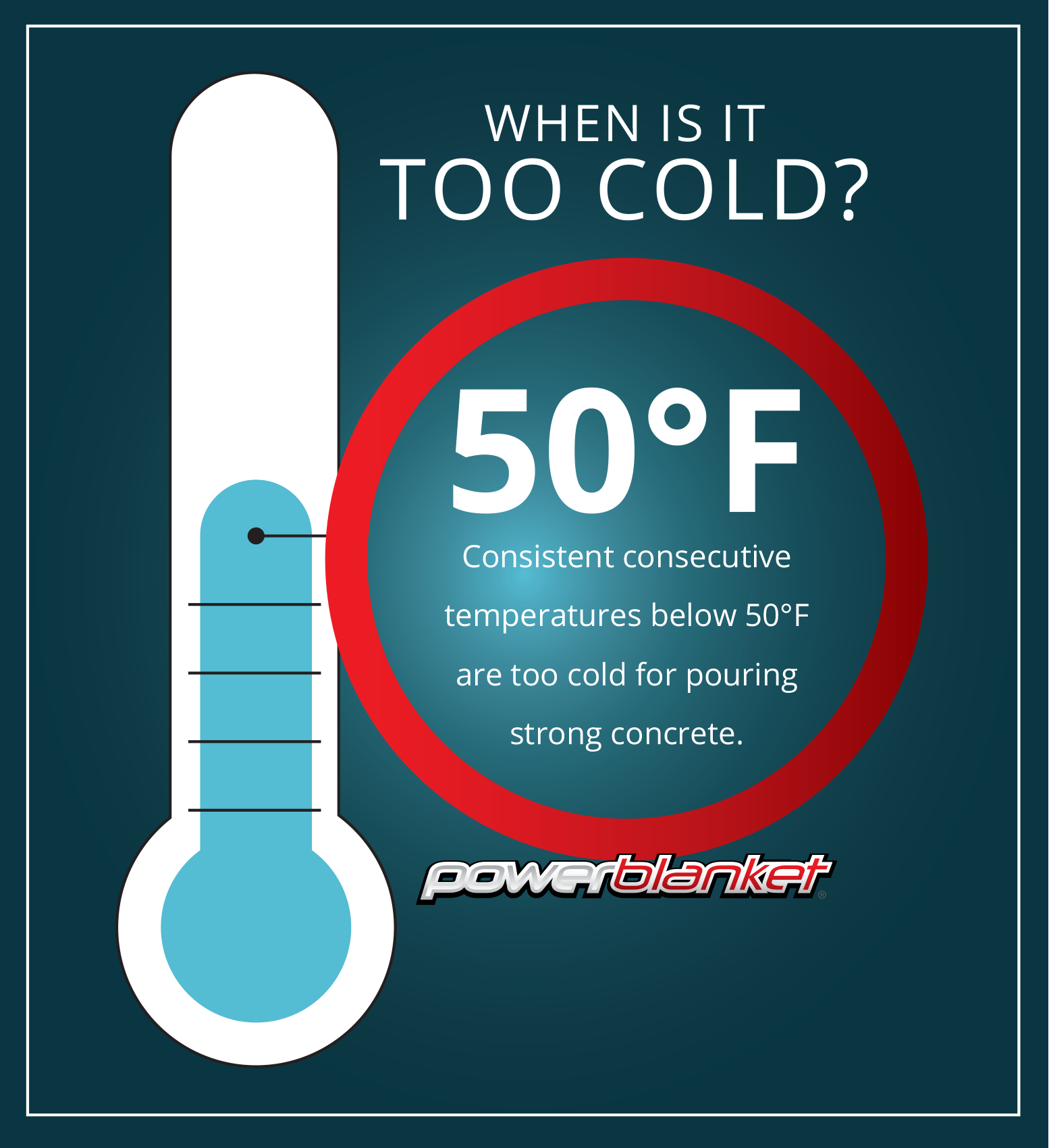

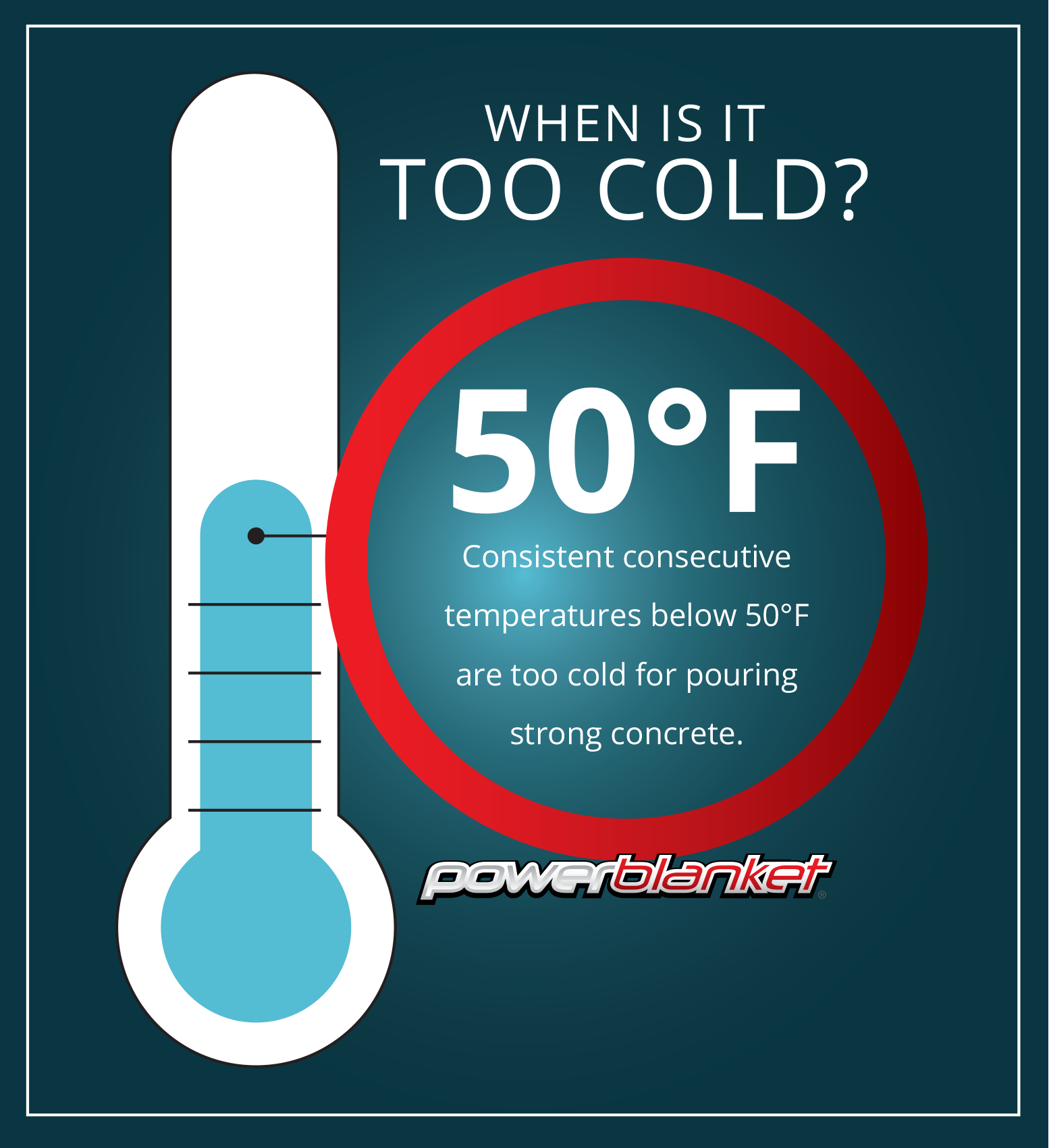

First let s define cold weather with respect to pouring concrete.

Pouring concrete walls in cold weather.

They all begin with protecting the ground beneath the foundation from frost snow and ice.

That is the chemical reaction between the water and portland cement actually creates heat.

Calcium chloride and non chloride accelerators ncas are proven to be very effective at accelerating the.

If possible avoid pouring concrete at noon or during peak times for hot air temperature.

When concrete is being managed under cold weather it must be protected from freezing shortly after being poured.

The reason insulation matters on cold weather pours is because concrete hydration is exo thermic.

An aggregate made up of sand and gravel and a paste made from a mixture of clean water and cement a fine powder made from a combination of finely ground and heated stone minerals ash and other products.

When pouring concrete in hot weather space control joints at smaller intervals than.

Also concrete must be able to develop the required strength for the safe removal of forms while reducing the circumstances where excessive heat must be applied to help concrete develop the required strength.

Actually there are safe effective ways to pour a concrete foundation in cold weather.

Concrete is a material made up of two core components.

10 best practices for pouring concrete in cold winter weather.

The rule of thumb is that if the concrete can be kept above 40 f for 24 hours it will reach design strength.

Any time you have three consecutive days where the average daily temperature is less than 40 f or if the temperature is lower than 50 f for less than half of any of the three days that is undesirably cold for concrete.

And do not pour concrete over frozen ground.

Ambient air temperature is the single biggest factor to consider when pouring during the winter months.

Due to the quantities and heat capacity of cement using hot cement is not an effective method in raising the initial concrete temperature.

The two biggest factors to consider in cold weather conditions are ambient outside air temperature and the time of placement of the concrete.

This is done before winter begins by covering the ground with hay and covering the hay with tarps or plastic sheets.

Another aspect of the decision process for cold weather concrete is the use of admixtures.

When the paste and aggregate are blended it creates a malleable semi liquid material that can be poured and shaped but when.